Insight R&D

Building lighter cars: an insight into R&D at Ford

Alan Banks, light weighting innovations manager at Ford Motor Company and a fellow of the IKE, writes about the company’s research project assessing composite hybrid structural suspension, which aims to help reduce the weight of future commercial vehicles.

Ford Motor Company is conducting research and development to quantify the weight saving, CO2 reduction and performance benefits of hybrid structural composite suspension elements for commercial vehicle applications.

As electrified vehicles become more mainstream, the weight of the vehicles is increasing. Weight will quickly become a priority for all manufactures as range and fuel economy are the biggest vehicle attributes affected by excess weight. This is especially true of commercial vehicles as available payload will also be affected. For commercial vehicle users, this is as important as range and economy – possibly more so.

With driving licences restricted to 3.5 tonne gross vehicle mass (GVM), the payload capacity is directly affected by increased weight of the unladen vehicle. Without addressing this issue, more commercial vehicles will be required on the road to move goods.

This project, known as Composite Hybrid Automotive Suspension System Innovative Structure (CHASSIS), is directly aimed at reducing the unladen weight of the vehicle thus improving payload, range and fuel economy with no loss of function or attributes to the driver.

Initiated by team members that won the 2018 JEC World Award for Automotive Application Innovation, the project is being undertaken by Ford’s Dunton facility, Gestamp UK, the National Composites Centre (NCC) in Bristol, and the University of Nottingham, and is designed to assess the feasibility of hybrid components replacing steel predecessors.

Project goals and methods

The project, partially funded by Innovate UK, is investigating composite hybrid structures for suspension crossmembers and lower control arms as well as solid axles comprised of metallic, carbon and glass fibre with different matrices to suit their loading conditions.

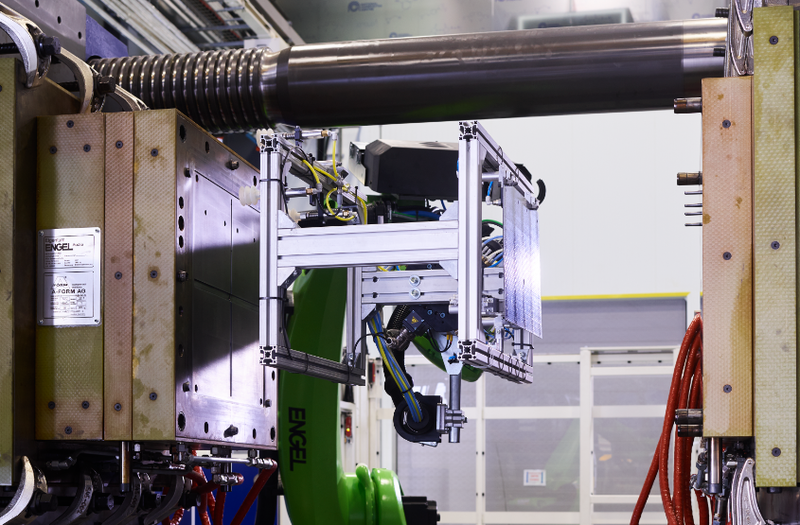

Manufacturing methods are still under review but could include overmoulding, pultrusion and compression moulding. Advanced joining techniques will also be utilised to meet volume production cycle times. The hybrid parts will accommodate all clevis requirements for attaching parts to meet current hard point locations, and comply with Ford Motor Co. noise, vibration and handling requirements.

Alan Banks, one of the report’s authors and the project leader, commercial vehicle supervisor at Ford, says the CHASSIS project is facilitated by the consortium’s expertise in finite element analysis optimisation, materials, manufacturing techniques and commercial vehicle requirements, which have accelerated the development. This helped to identify the correct material and manufacturing method for each component to be able to reduce the weight by an average of 40%.

“

The goal of the project is to develop components and processes with full production in mind, at a rate of around 500,000 vehicles per year globally."

Alice Swallow, an engineer at Ford Commercial Vehicle Suspension, explains that innovations of each component are tailored to ensure that they are able to meet the design requirements of the metallic counterpart. She adds that material selection, anisotropic in nature, helped the development of the tremendous anticipated weight saving and drove the manufacturing process to suit.

The goal of the project is to develop components and processes with full production in mind, at a rate of around 500,000 vehicles per year globally, according to Graham Rowland, another engineer at Ford Commercial Vehicle Suspension. He also notes that the business model and the customer needs would be the key to the deployment opportunities and whether further opportunities for the technology would be served across other Ford platforms.

Gareth Bone, innovation project manager at Gestamp UK, says without the knowledge transfer from other Innovate UK projects the company had partnered on, such as CLASS, LIGHTJOIN and ARCH, the material selection and early concept development would have required a much longer time period. The concepts which have been developed to date are defining the right materials in the right place to guarantee the production volume and cost targets are achievable while maintaining a circa 40% weight save over current steel parts

Ben Cross, technical project lead for the NCC, explains that the CHASSIS project enables the centre to bring together its expertise in material selection and manufacturing technology with the demanding challenges provided by the high-rate application. The project will also demonstrate the value of the NCC’s investment in latest generation of high-volume composite manufacturing process, including injection overmoulding.

The CHASSIS project aims to reduce the unladen weight of vehicles to improve payload, range and fuel economy with no loss of function or attributes to the driver.